As technology improves the advantages of using a solenoid over the typical motorized valves does increase in both homeowner usages and industrial uses for compressed air and liquid. Whether you are trying to open, shut off, split, mix, or move air, oils, gasolines, water supply, coffee makers, etc. the applications are endless.

There are a lot of advantages to using solenoids such as their speed and combination with automation equipment for streamlining processes is exceptionally effective. This is due to solenoid valves being able to automatically open and close by electromagnetic signals allowing automation processes to be controlled easier and more efficiently.

When you compare solenoid valves to other mechanical valves, often, solenoids will have a lower cost and can have a longer life cycle. They are also able to be rebuilt numerous times over, allowing the user to maximize the lifespan of the valve. Manufacturers often have replacement coils and rebuild kits that allow even a novice home user to do rudimentary maintenance to maximize the valve’s life and efficiency. Often these replacement parts are inexpensive.

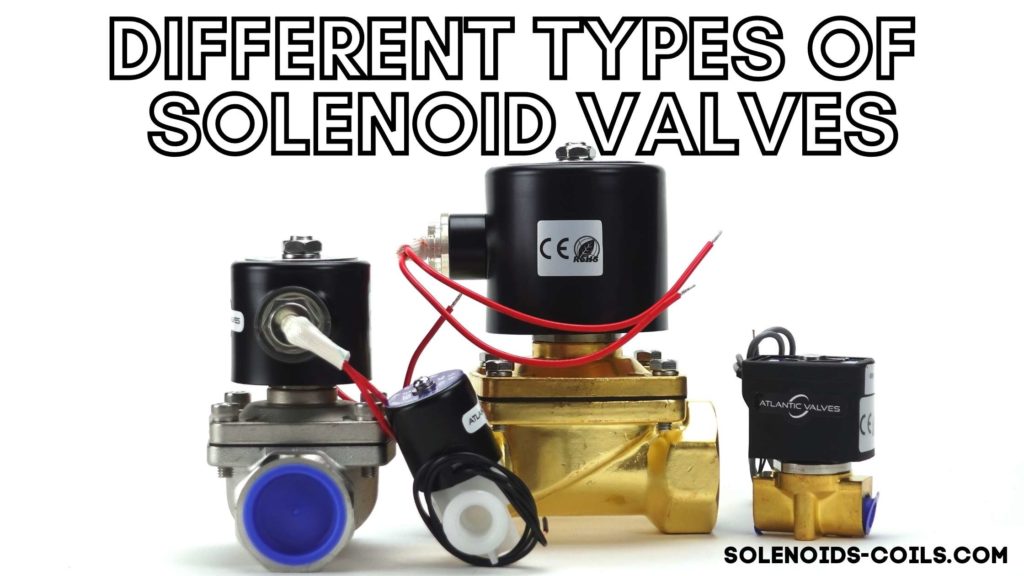

Solenoids can often be found in small and simple shapes that are designed to be installed in various locales and various positions depending upon the manufacturer’s instructions. They can also be found in numerous different materials that are suitable for almost any type of environment, temperature, division and class.

The fast response time is also ideal for many applications. Generally, solenoids will respond in less than one (1) second. Making them ideal in many health industries as well.

There are also manufacturers that make it easier to adjust voltages for their solenoid by simply replacing the coil with the correct voltage. This will allow a user to not have to un-plumb the valve but just re-connect the electric components with the new coil.

With all the advantages, often solenoids can appear to be the best valve for the job. But you will want to take into consideration the manufacturer’s tech specs and it is also always important to double check with the distributor or manufacturer of the valve to ensure that it is the best valve for your application.

When considering a solenoid valve for your application it is important to remember to discuss with your distributor or manufacturer how you intend to use the valve. They are an amazing resource to have. And some great things to discuss with them that can affect your application are:

- Continuous energization – Not every solenoid valve can be energized 24/7 without understanding that you may need to have replacement coils on hand. It is important to go over the limitations of the solenoid and if it was designed to be on for long periods of time or if a motorized ball valve is better for you.

- Depending on the manufacturer, a coil can generate quite a bit of heat. So, it is important to take this into account in the location of where you intend to install the valve. Some valves may require sufficient airflow, where others may not need it. However, the more extras you require the higher the price of the valve.

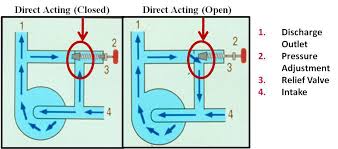

- Not all solenoids are bi-directional flow. So, it is important that if you have backpressure in your application that you discuss whether the valve can handle it or not – and always install the valve in the appropriate flow direction as indicated on the body of the valve.

- Always check the outdoor rating for the valve if you intend to install it where it will be exposed to the elements. Not all solenoids are outdoor rated, and many require some type of small covering to help protect against weather extremes.